|

|

COMPOSITE DECKS FOR PEDESTRIAN AND HIGHWAY BRIDGES

— 5-times reduction of installation costs,

— 10-times reduction of installation time,

— increase of the structure’s service life due to the 6-16 times reduction of the permanent load.

|

Factors |

Traditional materials | Composite |

| Weight, 1 m² | 640 kg | 40 kg |

| Repair periodicity | 5 years | 10 years |

| Service life | 30 years | 75 years |

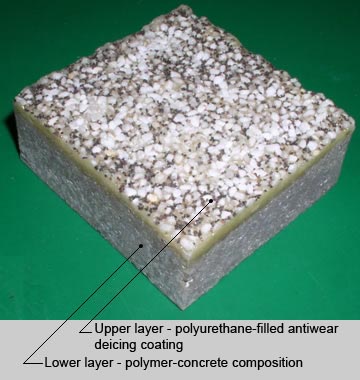

ANTIWEAR COATING «APATECH PB-M»

— Service life: 50 years,

— Wearing property: is 4 time less than allowable by GOST130150.0 (tested in Research and Scientific Institute of Reinforced-concrete)

COMPARISON OF HIGHWAY COATINGS

Laboratory of corrosion and durability of concrete and reinforced-concrete structures (RSIRC, 2004)| Material | Density, g/cm³ | Porosity, % | Water absorption, % | Strength, MPa | Frost-resistance, cycles | |

| compression | bending | |||||

| Road concrete Â25-Â40 | 1,8-2,5 | 10...15 | - | 32,7-52,4 | 5,9-6,1 | 200 |

| Bituminous concrete | - | Up to 22 | 0,5 | - | 5,5-6,5 | 50 |

| «ApATeCh-PB-M» | 1,8-2,5 | 9 | 0,045 | 57,2 | 16-25 | 700 |

| Ratio | 1 | 1-2,4 | 10 | 1,1-1,7 | 3 | 3,5 |

An average wearability of the coating “ApATeCh-ÏÁ-Ì” 0,169 g/cm², which is much more less than the value standardized in accordance with GOST 130150.0 (0,7g/cm²) for concrete structures

November 29th, 2013

November 26th, 2013

November 1th, 2013

| Railways | Highways | Bridge engineering | Infrastructure | Power engineering and communication | Transport | Subway |

|

|

© Apatech — Applied Advanced Technology Company Ltd., 2005—2007. All rights reserved.

Russia, 107078, Moscow,

Novaia Basmannaia 14 str. 2 |